ESA scientists have successfully demonstrated 3D printing of a metal part in space for the first time.

3D printing in space can be done in many ways. gravity It is used to position material during the printing process, as molten metal is often used as part of the filament, or printable medium, when creating metal structures. space,Its behavior is unpredictable and the lack of gravity can cause the filaments to shift or be placed in the wrong position, producing a poor quality object.

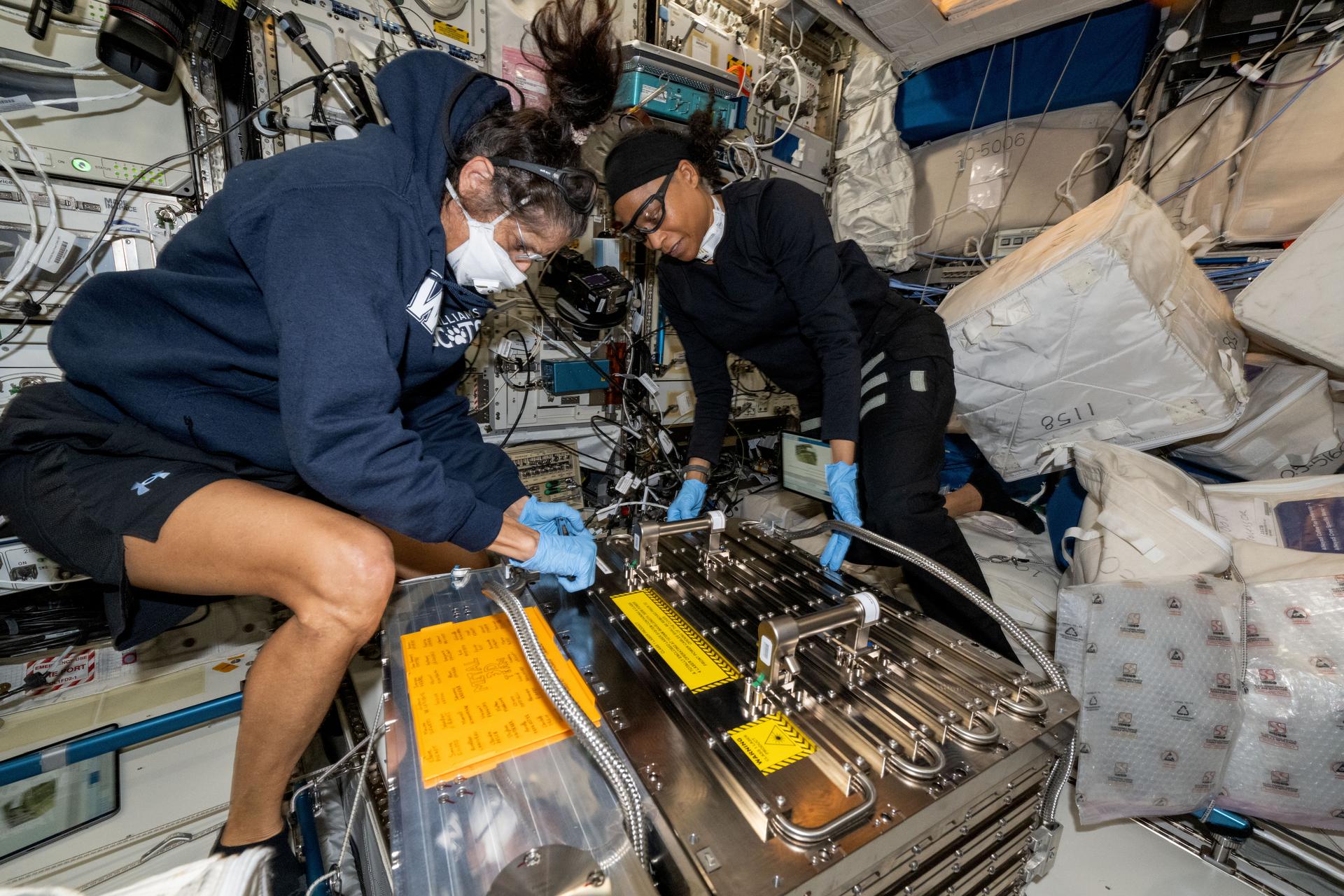

So scientists have had to adapt to working under these difficult conditions. International Space Station They had the perfect setup: ESA’s metal 3D printer uses stainless steel wire melted by a powerful laser that reaches temperatures of 2,192°F (1200°C) to create molten metal filament, which is then deposited layer by layer to build the desired shape.

After months of rigorous testing, the team finally adapted the printer to microgravity and successfully produced the first metal part in space in August 2024. The team plans to print two more objects before bringing all three back into space. Earth For quality analysis and future planning.

Related: Future lunar astronauts may use lunar minerals to 3D print their own supplies

“By printing the first metal 3D shape in space, the ESA exploration team has achieved a key milestone in establishing in-orbit manufacturing capabilities. This achievement, made possible by an international and interdisciplinary team, paves the way for long-distance and long-duration missions, where the creation of spare parts, construction parts and tools on demand will be essential,” said Daniel Neuenschwander, ESA’s Director for Human and Robotic Exploration. In a statement.

This groundbreaking technology continues to expand its range of applications on Earth, revolutionizing fields such as medicine, fashion, art, construction, food production and manufacturing. month And potentially Mars If this becomes a reality, astronauts will need the means to repair or create their own tools and parts for machines and structures that are difficult to fit aboard the spacecraft’s limited capacity.

As technology improves, it may be possible to print new tissues and organs in the future, improving our ability to sustain long-term space exploration, but this is still decades away.

3D printing in space is nothing new — microgravity provides an intriguing environment for scientists to conduct experiments, develop better 3D printing materials, and create structures that would be difficult to make on Earth — but what’s significant about ESA’s recent announcement is that this is the first time a 3D printer has successfully produced a metal part.

This capability marks a major milestone because, until now, metal parts for space missions had to be manufactured on Earth and transported into orbit, a costly and complex part of any mission.